What’s Inside RCU Control Boxes? A Complete Guide to Components, Logic, and Wiring

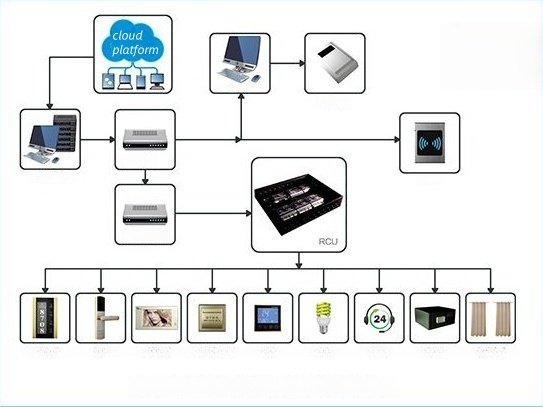

In industrial automation, smart homes, and security systems, the RCU (Remote Control Unit) control box operates as the “nerve center.” Though unassuming in appearance, it precisely regulates various devices through the coordinated work of internal components. This article breaks down the RCU control box, examining its core components, control mechanisms, practical applications, and optimal wiring strategies.

I. Core Components of RCU Control Boxes: Specialized Roles

The functionality of an RCU control box hinges on its internal components. While configurations vary slightly across industrial, residential, and commercial settings, the core components remain consistent:

1. Main Control Unit: The “Brain”

- Microcontroller (MCU): Devices like STM32, Arduino, and PLC modules serve as the core computing unit. They receive external commands (e.g., from remotes or sensors) and send control signals to other components based on preprogrammed logic, acting as the “decision-making center.”

- Memory: Stores control programs, operation logs, and parameters—ensuring data persistence even during power outages. Common types include EEPROM and Flash chips.

2. Input Module: The “Sensory System”

- Signal Receivers: Infrared receivers, RF modules, and Bluetooth/Wi-Fi modules capture commands from remotes, mobile apps, or other devices.

- Sensor Interfaces: Connect to temperature, humidity, light, and motion sensors, enabling the RCU to “sense” environmental changes for automatic control (e.g., dimming lights in low ambient light).

- Buttons & Knobs: Physical controls for local adjustments or emergency operations in some models.

3. Output Module: The “Actuators”

- Relays: The most common output components, using low-voltage signals to control high-voltage devices (e.g., lights, motors, valves)—enabling safe low-voltage control of high-voltage systems.

- Thyristors (SCRs): Ideal for power-adjustable devices like dimmable lights or variable-speed motors, providing smooth voltage/current regulation.

- Driver Chips: Power precision equipment such as stepper motors and servos, enabling accurate position or speed control when paired with the main control unit.

4. Power Module: The “Power Source”

- Transformer: Converts 220V AC to low-voltage AC (e.g., 12V, 5V) for internal components.

- Rectifier Bridge & Voltage Regulator: Converts AC to DC and stabilizes output to prevent voltage fluctuations from disrupting components.

- Backup Battery: Critical in security or medical settings to prevent device failure during power outages.

5. Protection Components: The “Safety Shield”

- Fuses/Circuit Breakers: Automatically cut power during short circuits or overloads to prevent component damage or fires.

- Varistors: Absorb transient high voltages from lightning or power surges, protecting sensitive components.

- Optocouplers: Isolate high and low voltages to prevent interference with the main control unit and ensure operator safety.

II. How RCU Control Boxes “Command” Devices: The Control Logic

The RCU control process follows a closed loop: signal reception → analysis → command execution. Here’s a step-by-step breakdown:

- Signal Input: External commands (e.g., remote button presses, app instructions) or sensor data (e.g., high temperature alerts) are transmitted to the main control unit via the input module. For example, a voice command to “turn on the living room light” in a smart home travels via Wi-Fi to the RCU’s main control unit.

- Programmed Analysis: The main control unit processes input signals using preprogrammed logic (e.g., “close the relay when a light-on command is received”). For sensor data, it compares readings to preset thresholds (e.g., “start the fan if temperature > 30°C”).

- Command Execution: The main control unit sends signals to the output module—for instance, closing a relay to power a light or adjusting motor speed via a driver chip to open curtains.

- Feedback & Adjustment: Advanced RCUs use sensors to monitor device status (e.g., “is the light actually on?”) and send feedback to the main control unit. Abnormalities (e.g., failed commands) trigger alarms or retry mechanisms.

This logic enables both manual and fully automatic control. For example, in industrial lines, RCUs adjust conveyor belts based on sensor-detected material positions; in greenhouses, they regulate irrigation using soil moisture data.

III. Core Functions of RCU Control Boxes: From Basic to Advanced

RCU capabilities range from simple control to complex integration, depending on the application:

- Basic Control: Switching devices on/off, adjusting speed/brightness (e.g., controlling streetlights, pumps, or air conditioners).

- Scheduled Control: Programming devices to operate at set times (e.g., “turn lights on at 6 PM and off at 11 PM”).

- Integrated Control: Coordinating multiple devices (e.g., “trigger alarms, lock doors, and start cameras when security is breached”).

- Remote Monitoring & Management: Uploading device status to the cloud via network modules, allowing users to check data, adjust settings, or diagnose issues via mobile apps.

- Emergency Protection: Automatically cutting power and alerting users during anomalies (e.g., leaks, malfunctions) to ensure safety.

IV. Real-World Applications of RCU Control Boxes

1. Smart Homes

In modern smart homes, RCUs orchestrate seamless environments. When a user activates “home mode” via a mobile app, the RCU’s Wi-Fi module relays the command to the microcontroller. The controller then sends signals to: close relays for living room lights, adjust curtain motors via driver chips, and activate the air conditioner at a preset temperature. Indoor sensors continuously feed temperature and humidity data to the RCU, which adjusts the AC as needed to maintain comfort.

2. Industrial Production Lines

On automotive parts lines, RCUs manage conveyors and welding robots. When materials reach a designated position, a sensor signals the RCU, which stops the conveyor via a relay and triggers the welding robot via its driver chip. During welding, temperature sensors monitor heat levels—if thresholds are exceeded, the RCU pauses work and activates cooling systems until safe conditions return, ensuring quality and safety.

3. Agricultural Greenhouses

In vegetable greenhouses, RCUs connect to soil moisture sensors, light sensors, and irrigation systems. When soil moisture drops below set levels, the RCU opens irrigation valves via relays. Simultaneously, light sensors guide shade adjustments: opening shades for low light or closing them to prevent sun damage. This precision maintains optimal growing conditions, boosting crop yields and quality.

4. Security Systems

In residential complexes, RCUs link infrared detectors, cameras, and alarms. When a breach is detected, the RCU triggers cameras, activates alarms, and sends alerts to security staff via mobile apps. Backup batteries ensure uninterrupted operation during power outages.

V. Wiring RCU Control Boxes: Safety, Stability, and Maintenance

Proper wiring is critical for performance—poor setups cause interference, malfunctions, or hazards. Key principles include:

1. Separate High and Low Voltage Lines to Avoid Interference

- Keep high-voltage lines (e.g., 220V power, motor cables) at least 50cm from low-voltage lines (e.g., signals, sensors) to prevent electromagnetic interference.

- Cross lines vertically if necessary; shield low-voltage lines with metal tubing for added protection.

2. Standardize Connections and Label Clearly

- Ensure secure connections (use terminal blocks instead of soldering to avoid loose joints). Use thick-gauge wires (≥1.5mm²) for high-power devices to prevent overheating.

- Label all lines with “input,” “output,” and device names (e.g., “living room light”) for easy maintenance.

3. Zone Layouts for Heat Dissipation

- Group heat-generating components (power modules, relays) in ventilated areas, away from sensitive parts (microcontrollers, sensors). Route input and output lines on separate sides to avoid tangling.

- Keep lines short and straight, with 10-20% extra space for future expansions (e.g., new sensors).

4. Prioritize Grounding for Safety

- Ground metal enclosures with resistance ≤4Ω. Use separate grounds for high and low voltage circuits to prevent leaks from affecting sensitive equipment.

- Seal boxes in humid/dusty environments (e.g., factories, basements) and apply waterproof glue to connections to avoid short circuits.

5. Setting Up RCU Circuits

Circuit design ensures stability—follow these steps:

(1) Define Circuit Functions

Identify which devices share circuits and their needs (e.g., simple on/off vs. dimming). For example, living room lights might share a circuit for coordinated control, while high-power devices (ACs, TVs) need separate circuits.

(2) Distribute Loads Appropriately

Calculate total power for each circuit to avoid overloads. Choose wires and protection devices (fuses, breakers) accordingly: lighting circuits should not exceed 10A, while power circuits (motors, pumps) use wires rated above maximum operating current.

(3) Design Topology

- Tree Structure: Ideal for hierarchical setups (e.g., factory lines with main and branch circuits for different sections).

- Star Structure: Suits scattered, independent devices (e.g., security cameras), where one device failure won’t affect others.

(4) Integrate Control and Protection Components

Add relays for on/off control, thyristors for power adjustment, and fuses/breakers in all circuits. Use optocouplers to isolate high and low voltages, protecting the main control unit.

(5) Test Circuits

After wiring, test device responses to RCU commands and verify protection components trigger during overloads/short circuits. Use a multimeter to check voltage/current stability.

Conclusion

Though compact, RCU control boxes are the “intelligent core” of automation systems. Every detail—from component selection to wiring—impacts their reliability. Whether optimizing industrial precision, enhancing home convenience, boosting agricultural efficiency, or securing spaces, RCUs play a silent yet vital role. This guide aims to clarify their operation, helping users leverage their full potential in daily life and industry.