Case

Jiahe Sewage Treatment Plant Project

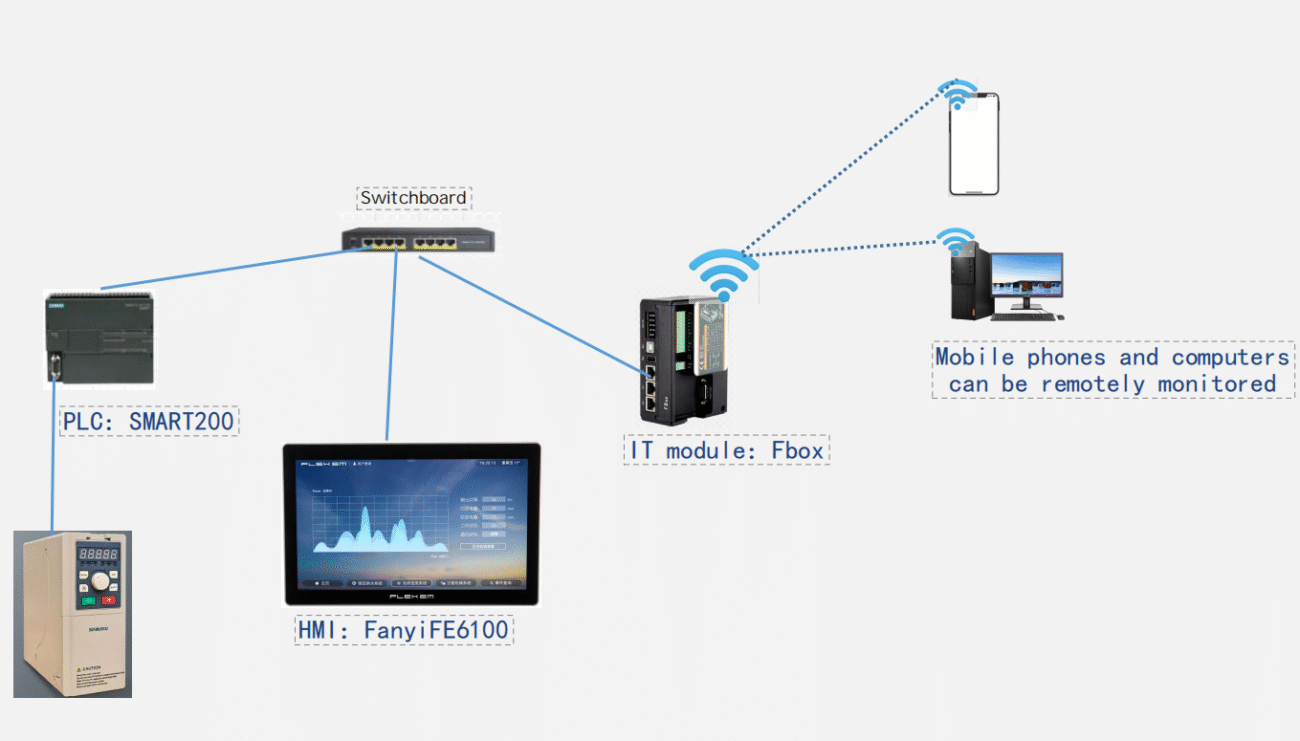

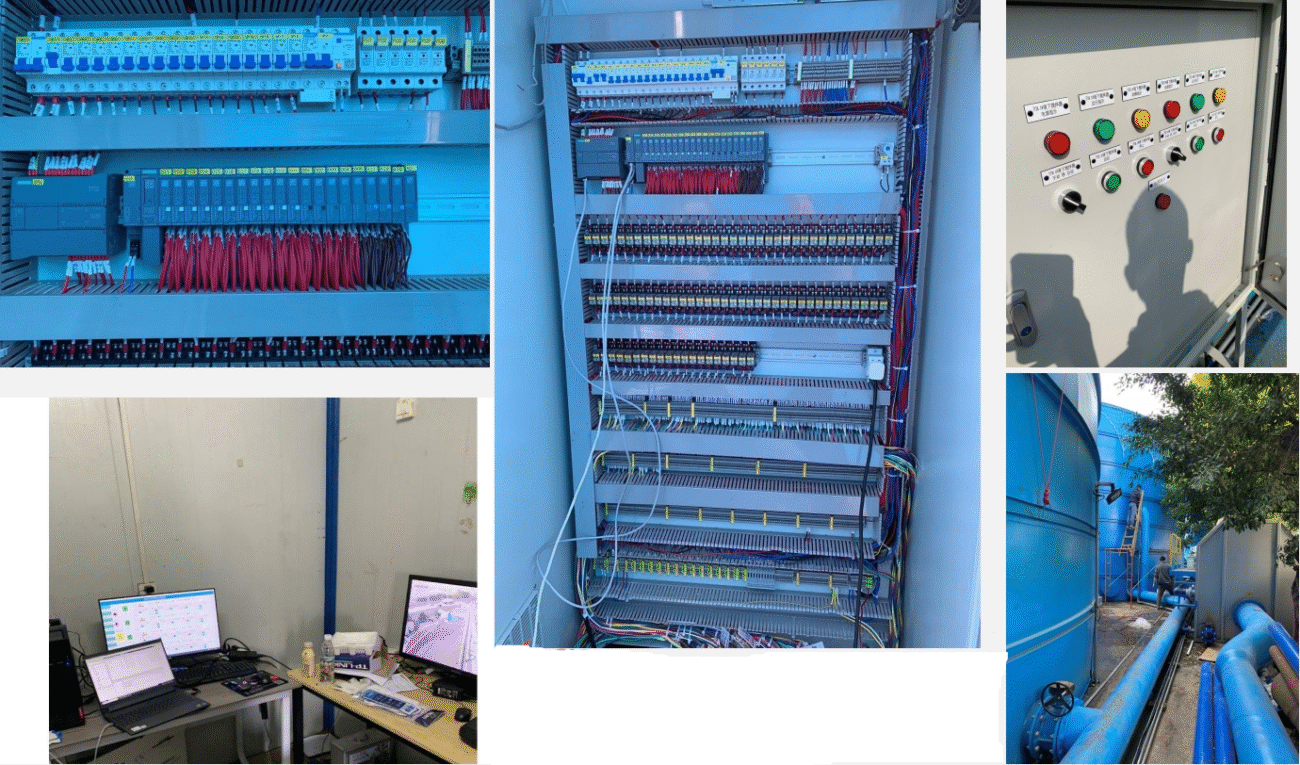

Centralized equipment control: It can centrally start/stop various equipment in the sewage treatment process, such as water pumps, fans, agitators, etc., and adjust their operating parameters to ensure that the equipment works collaboratively according to the set process.

Automation of technological processes: According to the requirements of the sewage treatment process, it automatically controls the operation timing of each treatment link, such as adjusting the switching of stages like water inlet, reaction, sedimentation, and water outlet, to ensure the stable and efficient operation of the treatment process.

Real-time monitoring and data collection: It real-time monitors data such as sewage flow, water quality indicators (e.g., pH value, COD), and equipment operation status, and transmits the data to the monitoring system, facilitating staff to grasp the treatment situation in real time.

Fault diagnosis and protection: It can promptly detect equipment failures such as overload and short circuit, automatically take shutdown protection measures, and send out alarm signals to reduce equipment damage and production accidents.

Optimized operation management: Through preset programs and algorithms, it optimizes equipment operation strategies. For example, it automatically adjusts the dosage of chemicals, fan speed, etc., according to changes in water quality and quantity, ensuring treatment effects while reducing energy consumption and operation costs.

Related projects