Case

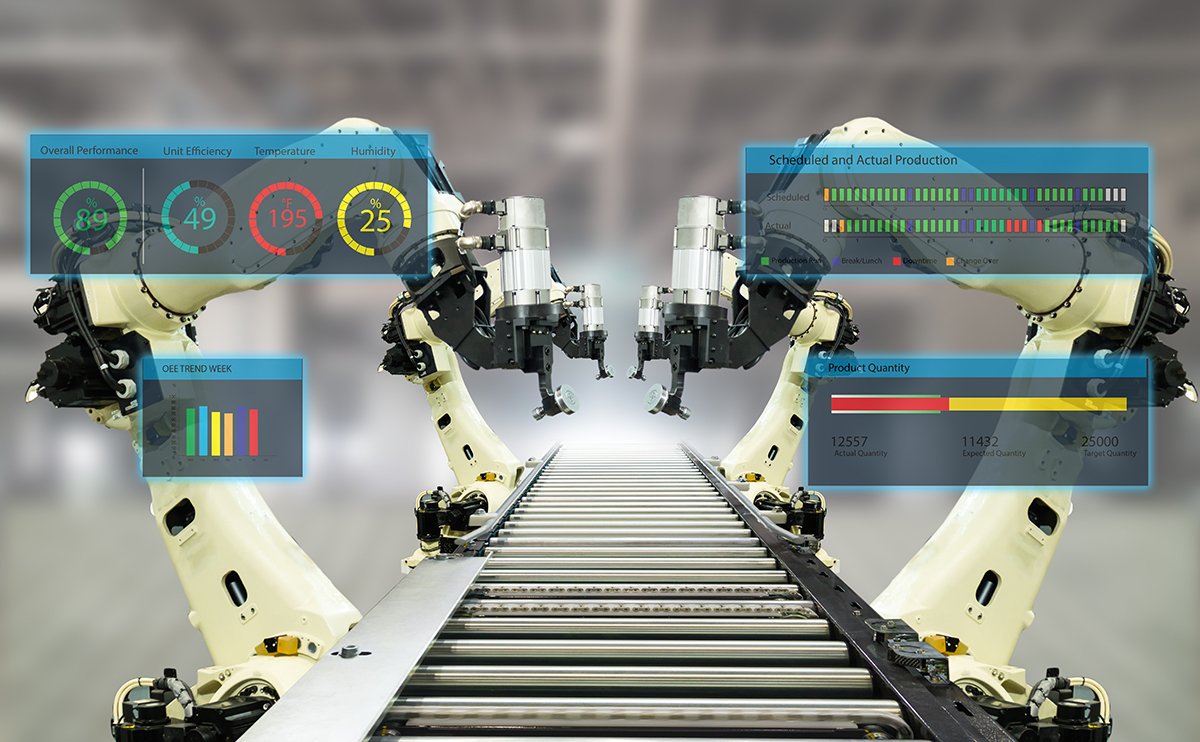

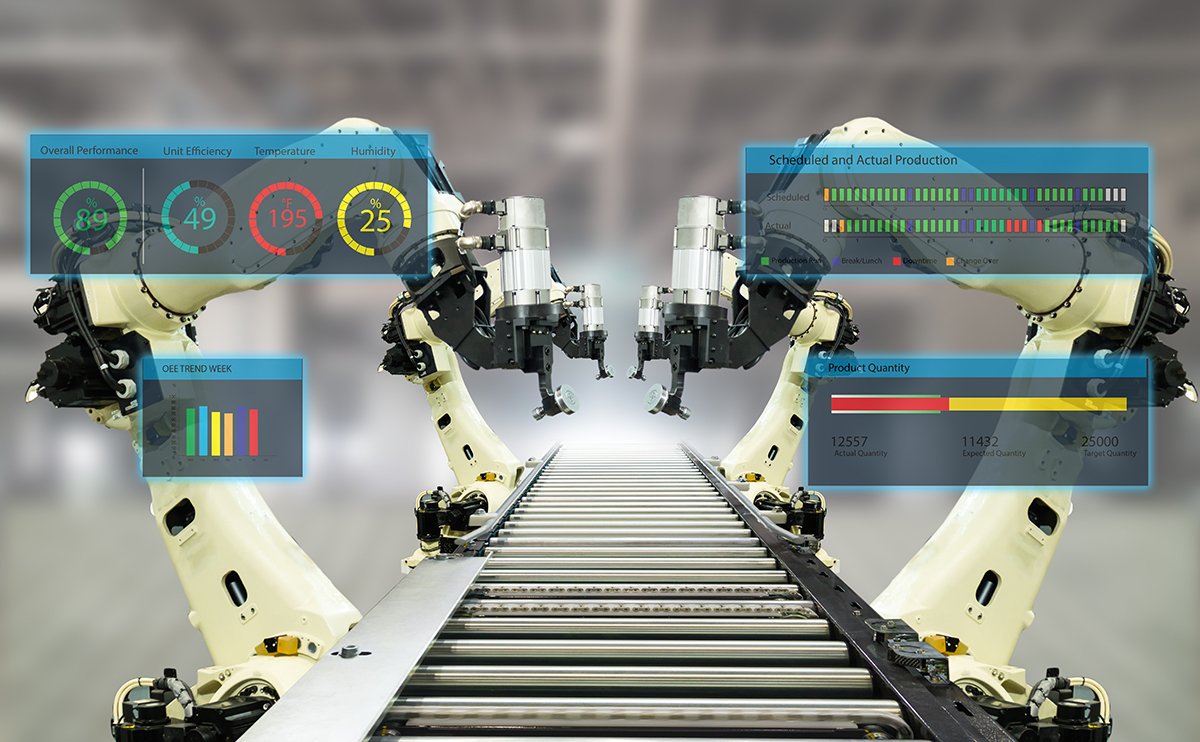

This explosion-proof control cabinet is designed for safe and efficient operation of condensation-evaporation systems in chemical plants. It integrates PLC Smart Line 1000, variable frequency drives (VFDs), sensors, and monitoring instruments to ensure precise control, energy savings, and real-time process monitoring.

Key Functions

1. Intelligent Control & Automation

- PLC Smart Line 1000

- Centralized logic control for pumps, valves, and heat exchangers.

- Pre-programmed sequences for startup, shutdown, and emergency protocols.

- Modbus RTU/TCP communication with SCADA for remote supervision.

- Variable Frequency Drives (VFDs)

- Adjust motor speeds of condensate pumps/fans based on load demand (20–50% energy savings).

- Soft-start functionality to reduce mechanical stress on equipment.

2. Real-Time Monitoring & Safety

- Sensors & Instruments

- Temperature/Pressure Transmitters: Monitor heat exchanger conditions (e.g., ±0.5% accuracy).

- Flow Meters: Track condensate/steam rates (e.g., Coriolis or magnetic types).

- Level Switches: Prevent tank overflows or dry-running risks.

- Explosion-Proof Design (Ex d IIC T6)

- Certified for hazardous zones (e.g., ATEX/IECEx).

- Pressurized enclosure with gas detection interlocks.

3. Operational Modes

- Auto Mode: Fully automated process control with PID tuning for optimal heat transfer.

- Manual Override: Local HMI (touchscreen) for maintenance or troubleshooting.

- Alarm Management: Audible/visual alerts + SMS notifications for critical faults (e.g., high pressure).

Related projects