In-depth Analysis of DDC Control Cabinets: The Core Engine of Building Intelligence and Cost Optimization Strategies

Building intelligence aims to achieve automated control and management of various equipment within a structure through advanced technological means, enhancing the building’s safety, comfort, and energy efficiency. The DDC (Direct Digital Control) control cabinet, as a critical component of building intelligence systems, precisely regulates various devices to ensure the efficient operation of the entire system. Its importance is comparable to that of a brain.

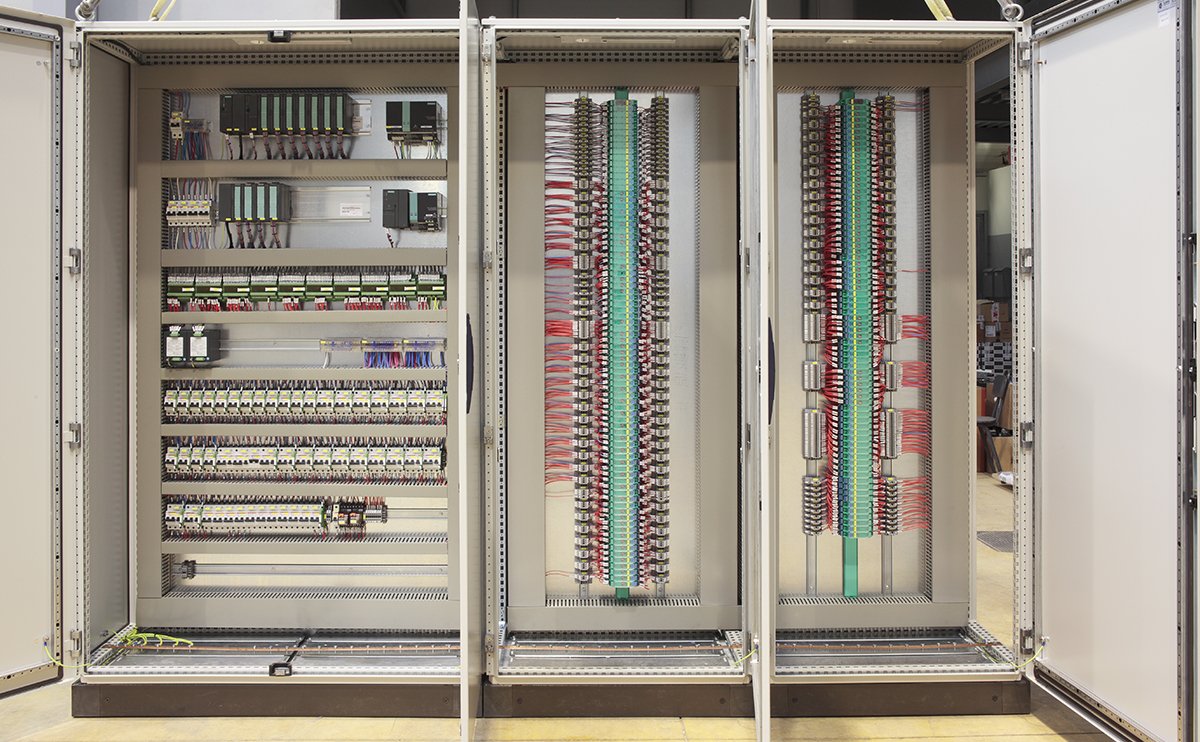

Working Principles and Structural Composition of DDC Control Cabinets

(1) Working Principles

The DDC control cabinet is centered around a microprocessor. It collects real-time data from various sensors—such as temperature, humidity, pressure, flow, and equipment status—through analog input (AI) and digital input (DI) channels. This data is then analyzed and processed according to preset programs and algorithms. After logical evaluation, control signals are issued via analog output (AO) and digital output (DO) channels to drive actuators, enabling operations like start/stop and adjustment of HVAC, lighting, water supply and drainage, and ventilation systems. The entire process is automatic and real-time.

(2) Structural Composition

Circuit Breaker: Serves as the main power switch for the cabinet, automatically cutting off power in case of overload or short-circuit faults to protect the control cabinet and connected equipment.

DDC Controllers and Modules: Selected based on project scale and complexity. Small projects may require only a single DDC controller with built-in outputs, while large projects may need multiple modules working in coordination with controllers, possibly even redundant configurations to enhance system reliability.

Power Supply: Provides stable electricity to all components within the DDC control cabinet, ensuring normal operation.

Relays: Act as signal converters and isolators. When the DDC controller’s output signals cannot directly drive control circuits, relays convert low-voltage, low-current control signals into high-voltage, high-current signals to meet circuit requirements.

Terminal Blocks: Connect internal components and external devices, facilitating signal and power transmission. Their quantity and specifications are configured based on the number and type of signals in the project.

Human-Machine Interface (HMI): Typically installed on the front panel for easy parameter setting, status monitoring, and control by operators. Widely used in environments with high operational demands, such as environmental protection and utility tunnels.

Applications of DDC Control Cabinets in Building Intelligence

(1) HVAC System Control

HVAC systems are a major energy consumer in buildings, and DDC control cabinets play a pivotal role. By deploying temperature, humidity, and pressure sensors indoors and outdoors, real-time environmental data is collected. When indoor temperatures deviate from set points, the DDC control cabinet quickly adjusts chilled or hot water valve openings to modulate HVAC capacity. It also controls fan speeds and fresh air intake based on indoor air quality. In large shopping malls, DDC-controlled HVAC systems can reduce energy consumption by approximately 30% by adjusting operations based on foot traffic and business hours.

(2) Intelligent Lighting Energy Savings

DDC control cabinets work with light and motion sensors to enable smart lighting management. During daylight hours, they dim or turn off lights when natural light is sufficient. In unoccupied office areas, lights are automatically switched off to avoid waste. In modern office buildings, DDC-controlled lighting systems with time- and zone-based strategies can save about 25% in annual lighting energy consumption while offering modes for work, meetings, and energy-saving scenarios.

(3) Stable Operation of Water Supply and Drainage Systems

DDC control cabinets monitor critical parameters like tank water levels and pipeline pressure. They automatically activate pumps to replenish water when levels are low and stop them when levels are adequate, preventing overflow. They also adjust pump speeds to maintain stable water pressure and detect drainage anomalies, triggering alerts for timely maintenance. A residential complex using DDC control cabinets achieved intelligent water management, reducing waste and operational costs.

(4) Security System Integration

In security, DDC control cabinets integrate with access control, video surveillance, and fire alarm systems. Upon detecting unauthorized entry, the cabinet links with cameras to display footage on security terminals. In fire emergencies, it shuts down HVAC fresh air intake to prevent smoke spread while coordinating elevator recalls and emergency lighting activation. A commercial complex using DDC integration successfully enhanced safety and prevented losses.

Reasons for the High Cost of DDC Control Cabinets

(1) Hardware Costs

Frame Materials: Options like cold-rolled steel, stainless steel, or aluminum vary significantly in cost. For example, 304 stainless steel is 40%-60% more expensive than standard steel but offers superior durability.

Internal Components: Brands like Schneider or Siemens cost 2-5 times more than domestic equivalents. High-end copper busbars and cables add 20%-30% to material expenses but ensure reliability.

(2) Functional Requirements and Customization

Special Features: Explosion-proof designs for metallurgy (25% cost increase) or IP66-rated cabinets for food industries (15% increase). Integrated temperature control or redundancy modules raise prices by 30%-50%.

Custom Design: Tailored engineering accounts for 5%-10% of total costs, with higher customization driving up expenses.

(3) Production and Quality Control

Manufacturing Processes: Automated production cuts labor by 20% but adds equipment costs. Hand-welded custom cabinets increase labor by 30%-50%. Surface treatments like electrostatic coating cost extra.

Testing and Certification: Compliance with CE, UL, or GB7251.1 standards adds 15%-25% to costs. Enhanced lightning protection (Level I to IV) raises material costs by 8%-12%.

(4) Market and Material Price Fluctuations

Supply-Demand Dynamics: High demand and limited supply, especially for premium or custom products, inflate prices.

Material Volatility: In 2023, cold-rolled steel prices rose 18% year-on-year, while copper cable costs fluctuated 5%-8% monthly. Chip shortages extended PLC delivery times to six months, with emergency purchases costing 50% more.

Strategies to Optimize DDC Control Cabinet Costs

(1) Rational Selection and Configuration

Needs Assessment: Avoid over-specification by aligning cabinet features with actual project requirements.

System Architecture: Distributed control using smaller DDC controllers improves reliability and reduces individual cabinet complexity.

(2) Localization and Supply Chain Optimization

Domestic Alternatives: Use locally sourced components where feasible, cutting costs by 15%-25% without compromising performance.

Supplier Partnerships: Secure stable supply and favorable terms through bulk or long-term contracts.

(3) Enhanced Production and Quality Control

Advanced Manufacturing: Automation improves consistency and reduces labor, offsetting initial investment over time.

Efficient QC: Streamlined testing protocols maintain quality while lowering inspection costs.

(4) Lifecycle Cost Management

Total Cost of Ownership: Factor in energy use, maintenance, and upgrades, not just purchase price.

Predictive Maintenance: Remote monitoring and diagnostics preempt failures, extending equipment life and reducing downtime.

Conclusion

As the core engine of building intelligence, DDC control cabinets are indispensable for enhancing automation, stability, and energy efficiency. Despite high costs, strategies like targeted configuration, localization, process optimization, and lifecycle management can improve cost-effectiveness. With advancing technology and maturing markets, DDC control cabinets will further drive buildings toward greater intelligence and sustainability. Future projects should prioritize their optimized application to maximize economic and social benefits.

Contact or add our WeChat: 13719269331