Case

Main Features:

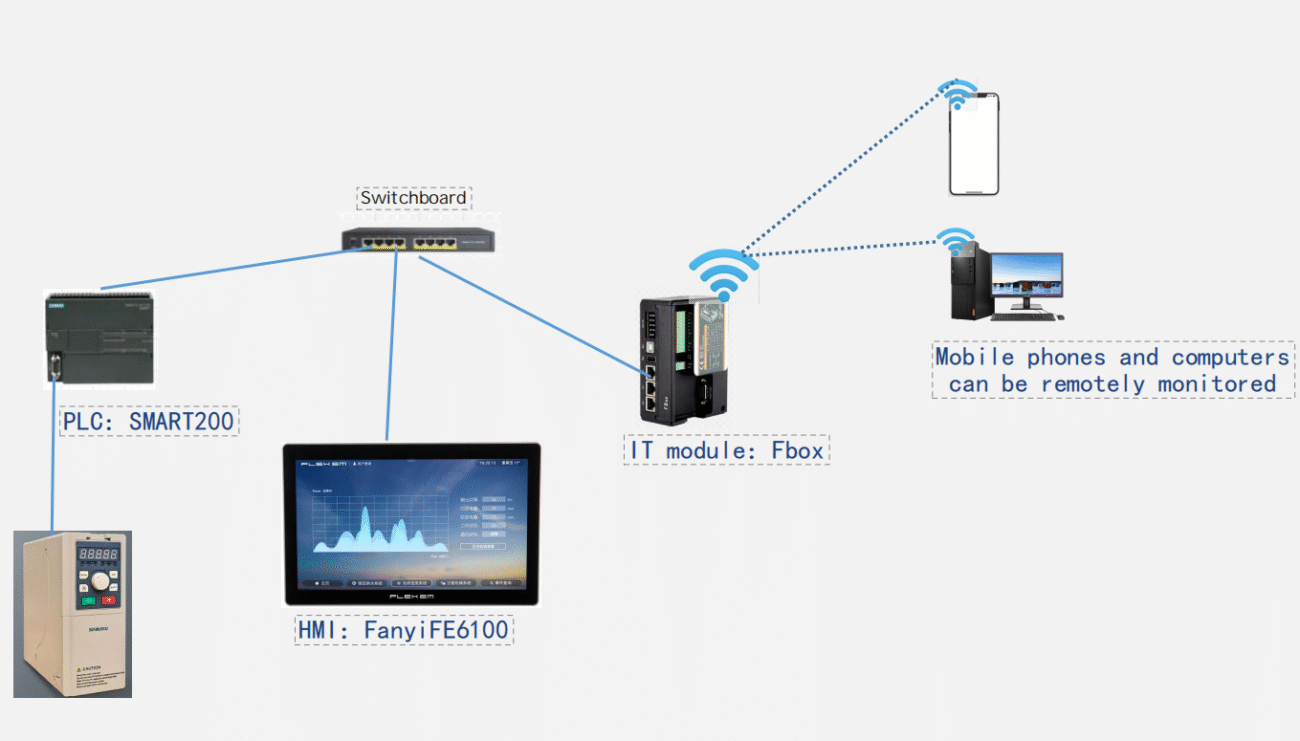

- Siemens S7-200 SMART PLC + Fanyi Touch Screen + FBox IoT Module + ABB Inverter

- Unmanned & Fully Automatic Operation

- Remote Monitoring via Mobile & Computer

- Fault Alarms with SMS Alerts – Effortless & Efficient

Core Functions

Self-diagnostic function minimizes manual inspections, lowering labor costs.

Automated Control System

Uses Siemens S7-200 SMART PLC for precise logic control, ensuring stable pump operation.

ABB Inverter adjusts motor speed based on real-time sewage levels, improving efficiency and reducing energy consumption.

Fanyi Touch Screen (HMI) provides an intuitive interface for on-site monitoring and parameter adjustments.

Remote Monitoring & IoT Integration

FBox IoT Module enables real-time data transmission to cloud platforms, allowing remote access via PC or mobile apps.

Operators can check pump status, flow rates, and fault logs from anywhere, ensuring timely intervention.

Intelligent Alarm System

Detects abnormalities (e.g., pump blockage, power failure, high water levels) and triggers instant SMS alerts to maintenance staff.

Reduces downtime and prevents overflow risks.

Energy-Saving & Low Maintenance

ABB inverter optimizes pump speed, cutting power usage by 20-30% compared to fixed-speed systems.

Related projects