PLC Empowers Commercial Intelligent Lighting: The Core Technology for Reshaping Smart Lighting Environments

In the energy consumption structure of commercial buildings, lighting accounts for as high as 30% – 40%. With the advancement of the “Double Carbon” goals and the surging demand for intelligent upgrades, commercial intelligent lighting systems are undergoing technological transformations. Programmable Logic Controllers (PLCs), with their powerful logical operation capabilities, precise control, and stable performance, have emerged as a key technology in constructing intelligent lighting systems.

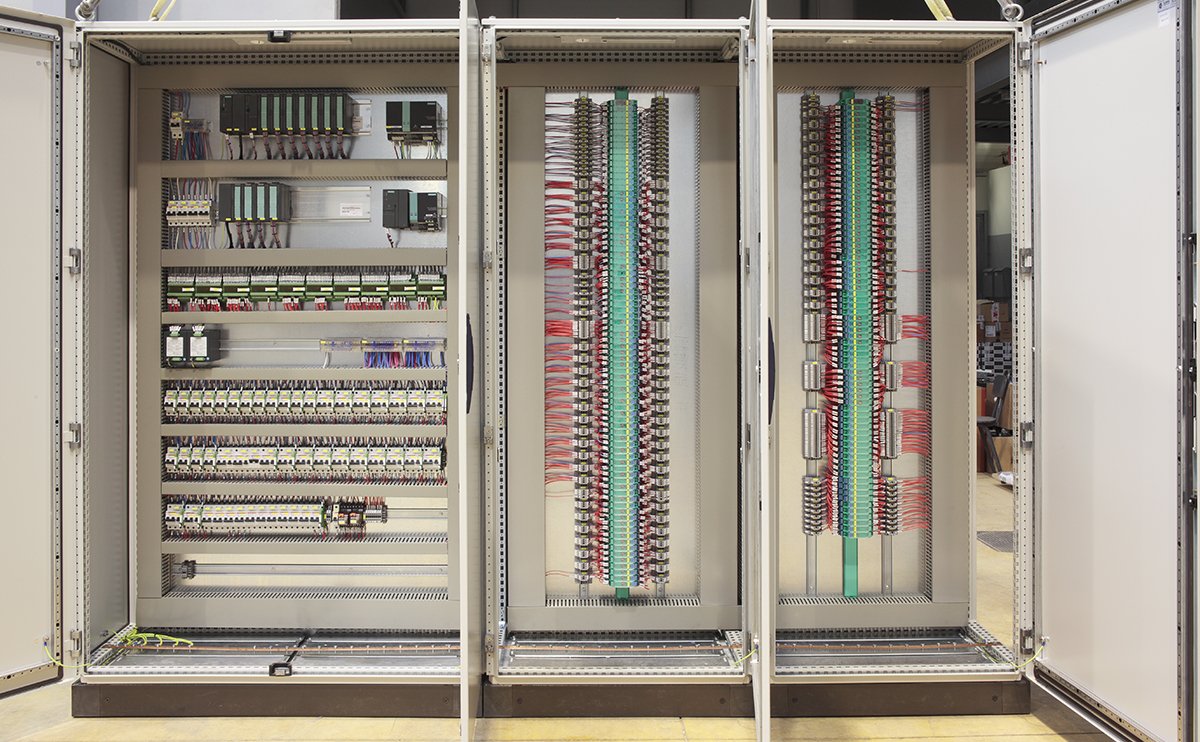

I. The Core Architecture of Intelligent Lighting Enabled by PLCs

PLCs are essentially industrial-grade microcomputers. They collect environmental data through input and output modules and achieve closed-loop control of lighting devices through internal program logic operations. Their core functions are as follows:

- Multi-source Data Fusion and Processing: PLCs integrate signals from devices such as light sensors, infrared sensors, and time controllers to establish complex lighting control logics. For example, when natural light is sufficient during the day, artificial lighting is automatically turned off; when no people are detected in an area, a time-delay switch-off mechanism is triggered.

- Modular Hierarchical Control: PLCs support area division and device grouping. Through communication protocols such as RS-485 and Modbus, they enable distributed management of LED luminaires, dimming modules, and switching power supplies. Large commercial complexes can thus achieve refined control by floor and business type.

- Fault Diagnosis and Early Warning: PLCs monitor electrical parameters such as current and voltage in lighting circuits in real-time. By using built-in algorithms to identify abnormal states, they can promptly send out fault information, reducing maintenance costs.

II. The Application Matrix of Intelligent Lighting across Scenarios

Thanks to their flexibility and scalability, PLC technologies have formed a rich application ecosystem in commercial scenarios:

- Intelligent Office Spaces in Office Buildings: In open-plan offices, PLCs work in conjunction with occupancy sensors and ambient light sensors to achieve adaptive adjustment of workstation lighting. In conference rooms, different lighting scenarios, such as projection mode and meeting mode, are automatically switched based on reservation systems.

- Smart Lighting Control in Commercial Complexes: In the atriums of shopping malls, dynamic dimming systems are used. PLCs automatically generate lighting shows with different color temperatures and brightness levels according to day and night cycles, holidays, and promotional events. In underground parking lots, microwave sensing control systems that “turn on lights when vehicles arrive and turn them off when vehicles leave” are deployed, reducing energy consumption by more than 60%.

- Intelligent Guest Room Systems in Hotels: Guest room control panels are connected to PLCs, enabling one-click switching between scenarios like “welcome mode,” “sleep mode,” and “reading mode.” In corridors, a combination of infrared sensing and time control is adopted, maintaining 30% of the basic lighting when no one is present.

- Precise Lighting Control in Cultural Venues: Museums and art galleries use PLCs to create professional lighting environments with low illuminance and no ultraviolet rays. Combined with display case movement detection, they achieve refined protection of exhibits.

III. Empirical Analysis of Energy Efficiency

The energy-saving effect of PLC intelligent lighting systems is achieved through the integration of multiple technologies: dynamic dimming reduces unnecessary lighting, time- and area-based control avoids energy waste, and extended device lifespan reduces replacement costs. For instance, in a Grade A office building, after the transformation, the annual energy savings rate of the lighting system reached 42%, saving over 800,000 yuan in electricity bills annually. In a large shopping mall, after applying the PLC system, the proportion of lighting energy consumption decreased from 38% to 23%, demonstrating significant energy-saving benefits.

According to statistics from third-party institutions, intelligent lighting systems using PLCs can generally achieve an energy-saving rate of 35% – 60%. Additionally, by reducing the frequency of luminaire replacements, maintenance costs are reduced by approximately 25%. With the deep integration of Internet of Things (IoT) technologies and PLCs, future intelligent lighting systems will further develop towards cloud-based collaboration and AI-driven predictive control, continuously unlocking the energy-saving potential of commercial buildings.